Industrial Designer

As the sole product designer for Hyundai L&C Canada, I partnered closely with the US-based Creative Director while independently managing the full design process in Canada. My role extended far beyond traditional design boundaries — from early research and concept development to laboratory prototyping, CMF strategy, and full-scale production. This position placed me at the intersection of design, engineering, and manufacturing, where I was responsible for ensuring that every idea was both innovative and production-ready.

My mandate was to create forward-looking surface designs that balanced market readiness with manufacturing feasibility. Working within a lean team meant I had direct input on every stage of development, from defining new tooling and testing methods to addressing challenges during production trials. Applying advanced design-for-manufacturing principles and leading CMF initiatives, I pushed the technological capabilities of our production process while aligning new products with brand vision and customer expectations. By staying deeply engaged in both strategy and execution, I was able to help the company deliver surfaces that were not only aesthetically compelling but also scalable, cost-effective, and aligned with evolving market trends.

Due to NDA restrictions, each step of my design process will be pulled from separate projects and be explored independent of each other.

Research is more than a phase — it is the foundation of the entire design process. I believe that in any company, design is the one discipline that must advocate for the end user. Engineering teams will focus on optimization, production teams will focus on efficiency, and finance will focus on cost. But it is design’s responsibility to ensure that the human perspective remains central to every decision.

My approach to research begins with people. I listen to clients, sales teams, and customers to understand not only how products are used, but also how they are experienced. From there, I expand outward — studying cultural trends, attending design fairs such as IDS Toronto and KBIS, and observing material and aesthetic shifts across adjacent industries. I approach these opportunities with curiosity, believing that insight can be found in the smallest of details, whether in a mass-market product or in the design of an everyday object.

This deliberately expansive lens allows me to synthesize diverse influences into meaningful directions for new product development. The result is research that is not only comprehensive, but also empathetic — transforming market data, cultural movements, and generational shifts in taste into design opportunities that reconnect the product with its user.

At Hyundai, concept development was both creative and strategic. I generated original design directions that reflected cultural and market shifts while challenging the limits of production technology. Each concept report I developed was reviewed at the director and executive level, giving me visibility at the very top of decision-making. I collaborated closely with development engineers to evaluate cycle times, tooling feasibility, and scalability, creating CAD models and technical drawings to communicate design intent in precise, production-ready terms.

Concept development at Hyundai combined creative exploration with executive visibility. I generated original surface design directions that reflected cultural and generational shifts while stretching the boundaries of production technology. Each concept package I produced was reviewed by directors and executives, positioning my work as a driver of strategic decision-making. To ensure feasibility, I collaborated closely with development engineers, translating design intent into precise CAD models and technical drawings that bridged design and engineering.

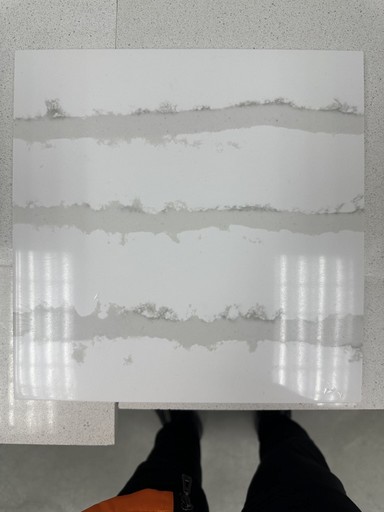

The laboratory was where concepts became tangible, and I had the privilege of leading and managing the lab team. I directed testing strategies, set parameters, and coordinated workflows to make sure our small group could deliver results quickly and accurately. At the same time, I chose to stay hands-on. By preparing pigments and pastes myself, I was able maximize first pass accuracy by making real time adjustments in my formulations. Handling this step personally both protected quality and accelerated progress.

Staying involved also allowed me to support the team directly. To maximize efficiency during high-pressure periods, I took on post-processing duties such as pressing, baking, cutting, and polishing slabs. This freed the technicians to focus on what they did best, producing sample slabs at speed. Normally one slab per day was the standard, but by handling secondary tasks myself I enabled the team to create two, doubling our output when doubling our testing visibility meant saving on costly additional full scale production trials. This combination of leadership and hands-on support ensured that the lab could consistently meet demanding timelines without sacrificing accuracy or creativity.

Prototyping at Hyundai extended beyond surface finishes into capability-building. I led tooling experiments using 3D printing and CNC machining to test new effects and address production challenges. Once proven at the lab scale, these prototypes were validated on the robotic arms of the full production line.

Tooling was where I often pushed boundaries. I viewed it as an opportunity not only to create design effects, but to expand what our manufacturing system could do. Working with our 3D printer and CNC machine, I developed scaled tooling prototypes that could be quickly tested in the lab. After proving feasibility, I partnered with engineers to integrate those designs into full-scale production, bridging concept with reality.

One of my most impactful initiatives was introducing a new ceramic coating process for tooling. The existing process was slower and limited in detail, so I sourced alternatives directly from suppliers, brought in samples, and worked with engineering to validate performance. This change delivered faster turnaround and higher precision, demonstrating my ability to identify bottlenecks, take initiative, and drive solutions into practice.

My role in tooling underscored the way I combined creativity with technical leadership. By guiding experiments, collaborating with engineers, and taking ownership of supplier engagement, I was able to advance Hyundai’s production capabilities while ensuring that design intent carried through to manufacturing.

The final stage of development was validating concepts on the full production line. On trial days I worked closely with the production team, documenting each run and making real-time adjustments to testing parameters as new variables emerged. My role was to ensure trials remained both rigorous and adaptable — balancing the plan with the realities playing out on the line. After each trial, I authored detailed reports outlining objectives, outcomes, post-trial assessments, and next steps. These reports were delivered directly to management, directors, and executives, positioning my work not only as hands-on testing, but as a structured decision-making tool that guided strategic direction.

My time at Hyundai L&C Canada reinforced my belief that strong design is inseparable from manufacturing knowledge. Being embedded in every phase — research, concepting, lab experimentation, tooling innovation, and production trials — gave me a holistic perspective that few design roles offer. I learned to move fluidly between creative exploration and technical precision, and to push the boundaries of what materials and processes could deliver while keeping user needs and production realities in focus.